Read the New Application Brief

Project Overview

During the Covid-19 pandemic, medical device suppliers saw a surge in production and fulfillment volumes. One multinational company that provides ventilation devices, technologies, and consumables found that their employees were making costly errors during a period of extreme caution. This company collaborated with Matthew Automation to implement warehouse automation in their US manufacturing and distribution facilities.Read how Matthews’ warehouse execution system (WES) software enabled the supplier to optimize and automate their complete fulfillment process with several leading material handling technologies and manage them together as one orchestrated system.

Read the Medical Products Supplier Application Brief:

Key Technologies Featured in the Brief

Matthews’ WES connects and manages several distribution and fulfillment sub-processes and types of material handling equipment including:- Order wave downloads

- Goods-to-person picking

- Put away storage policies, location policies and zone management

- Clean room carton creation and induction

- Automated print and apply on empty cartons coming from the carton erector

- Conveyor leading to a robotic arm that places products into the empty cartons

- Carton sealing and induction

- Interface with a Columbia palletizer that manages SKU-Lot runs

- Interface to Wulftek pallet finishing line

- ASRS putaway from the palletizer

- Induction to Kardex LR 35 vertical lift module

- Induction into Swisslog crane

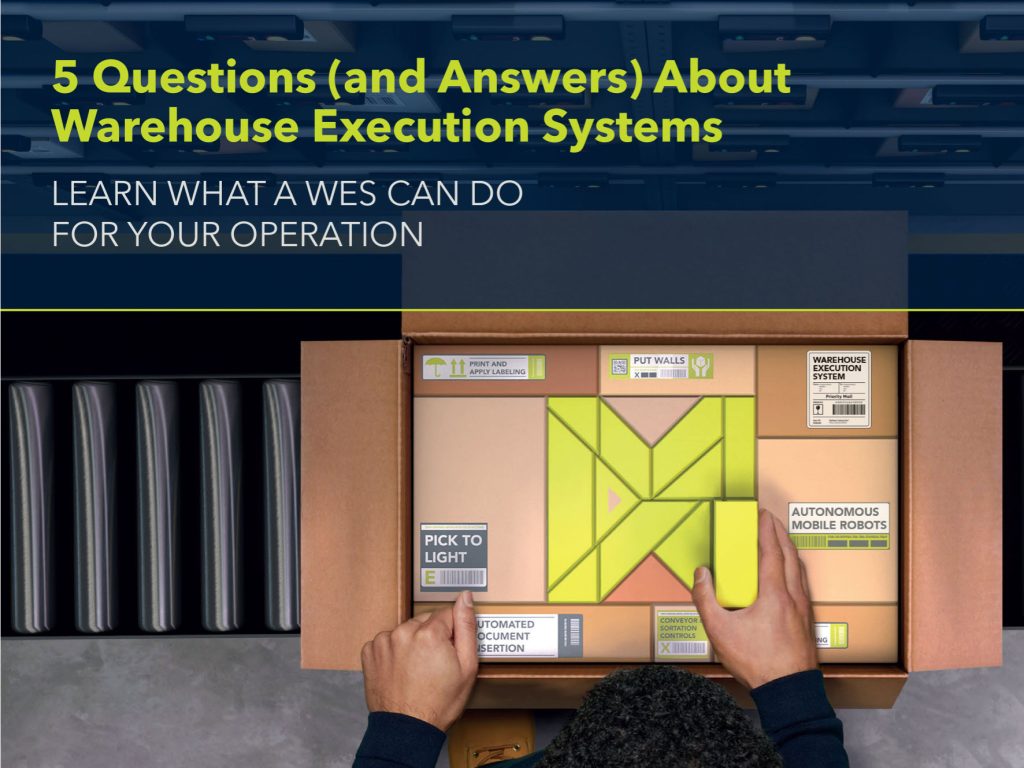

WES EBOOK

5 questions and answers about Warehouse Execution Systems.

Learn what our WES can do for your operation.