This post is first in a series about light-directed systems for 3PL operations.

Light-Directed Solutions Increase Throughput and Accuracy for 3PL Operations

The benefits of pick-to-light systems are well known by 3PL and 3PF managers, but there has been a misperception that the technology lacks the flexibility these operations require.

In fact, the opposite is true.

When properly engineered and supported by the right software, there are light-directed picking and sorting applications available that can actually provide tremendous flexibility to 3PLs: optimizing diverse product stock keeping units (SKUs), multiple accounts, unique requirements, seasonality spikes and fluctuating order volumes.

Whether using a single light-directed automation product, or multiple solutions for an integrated fulfillment system, properly engineered technologies simplify complex 3PL operations and reduce associated costs. Other advantages include:

- Support of multiple product lines and customers with a single, common hardware set. Freedom to move automation where needed as shifting product demands dictate

- Hardware modularity allows for incremental expansions.

- Capacity gains support current and future growth projections.

- Easy to train new employees for faster productivity.

- Segregation of cart-based batch picking by product lines or clients to optimize travel paths.

- Lot capture and verification for food and beverage handling, pedigree tracking for medical and pharmaceutical applications, and more.

- Dynamic location re-configuration for easy switching between different customer lines in the same rack, shelving or other storage media.

- Integration with, or management of, complementary automation such as container routing, print-and-apply labeling, weigh stations, quality control (QC) workstations.

Here are some of the picking technologies 3PLs have used to optimize their dynamic environments:

Picking Carts

A cart-based light-directed picking system enables batch picking of multiple orders at the same time—maximizing each picker’s pass through a warehouse. Carts can be outfitted with multiple shelves, customized to virtually any size or shape, and equipped with a variety of options, including powered versions for handling heavy loads.

On the face of each pick cart shelf, individual light modules are mounted at every discrete order location. The modules feature both electronic messaging displays as well as an illuminated push button for pick confirmation. When the picker arrives at an assigned storage area, the cart’s light-directed picking modules indicate which items should be distributed to each bin riding on the cart. (For this reason, pick-to-light on mobile pick carts can also be called put-to-light because the picked items are sorted, or put, into the indicated destination.) The modules also display the required quantity per order.

Because the modules are applied to the mobile cart, rather than to each unique static storage position or pick face, light-directed pick cart automation can be used with an unlimited number of SKUs and customers. This dramatically lowers installation costs. Further cost savings are realized by the elimination of conveyor for pick movement or transport, as the picks ride on the cart.

The ideal light-directed pick cart vendor provides not only the software to organize each cart’s picks and guide the picker’s travel along the shortest route, but also integrates batch optimization functionality. This feature tracks each cart’s real-time location in the warehouse (as opposed to assuming the cart is following a pre-determined route) and directs the picker to collect additional, single-line picks along the travel path while navigating to the completed order drop point.

Light-directed pick carts can be used alone, or as part of an integrated order fulfillment system that includes other automated equipment, such as put walls.

Put Walls

Space-efficient and economical, put walls (or put stations) utilize light-directed picking modules for high-speed, semi-automated sortation of mixed SKU products—batch picked with picking carts or other methods. They optimize high-speed, high volume, one- and two-line order sortation operations in a de-consolidation process sometimes called “pick-to-light in reverse.”

Constructed as a series of shelves that have been divided vertically into multiple cubby openings (or that hold empty bins or totes), each space represents a unique customer order. Most put walls are open on both front and back, with each opening equipped with a unique light-directed picking module, one per side.

After a tote filled with larger quantities of mixed products required to fill orders arrives at the put wall’s sortation (or put) side, the operator begins the de-consolidation process by scanning an item’s barcode. The scan triggers the light modules to illuminate, indicating the put location and quantity of the item required to fill that unique order. The operator sorts the products into the designated locations, then presses a button to confirm that the order is complete. This triggers corresponding lights on the pack-out side of the put wall to illuminate, letting packers know when a completed order can be taken away for final packing.

The ideal put wall supplier offers further productivity enhancements—such as LED lighting within each destination cubby that illuminates simultaneously with the modules to increase visibility, or photo-eye sensor driven touchless task confirmation that automatically detects item placement without requiring a press of the push-button—to help operators sort faster.

Light Frames

Mere inches thick, portable or fixed light frames are sturdy, welded metal structures equipped with pick-to-light modules across horizontal spans positioned at a variety of heights. The modules are spaced at pre-determined intervals that align with the pick faces or storage bays within a rack or shelving system. When outfitted with casters, the frames can be wheeled to a static storage position; alternately, portable storage units can be wheeled to fixed location frames.

Ideal for picking fast- and medium-velocity, broken case quantity SKUs, light frames enable a pick-to-light solution to be applied flexibly while significantly lowering installation costs. Because the modules are applied to the light frame—rather than to each unique static storage position or pick face—the pick-to-light automation can be used with an unlimited number of SKUs and customers.

Software

The ideal light-directed picking and order fulfillment execution software interfaces with one or more WMS utilized by a 3PL or 3PF—depending on their customers’ requirements—via electronic data interchange (EDI) plug-ins to pull, organize and optimize the SKUs required for order fulfillment. Additionally, the software should track lots and other secondary characteristics, as well as alert pickers to additional verification or special handling requirements associated with a given SKU.

The same software flexibly and adaptably drives the light modules, regardless of their installation format (pick cart, put wall or light frame), sequencing and coordinating their independent functions and simultaneous interactions with other automation and equipment.

It should also be capable of controlling and directing cross-product combinations of automation technologies, such as integrated cart and put wall systems. When controlling pick carts, the software should feature integrated batch optimization functionality to track each cart’s real-time location in the warehouse, and direct the collection of additional, single-line picks along the travel path.

Further, the software enables dynamic location assignment, allowing a light-module system to be easily reset to pick orders for multiple 3PL clients from the same storage areas during different timeframes or shifts as needed. And the platform itself should be scalable and modular, enabling the addition of more light-directed picking modules and solutions as a 3PL’s operational needs change.

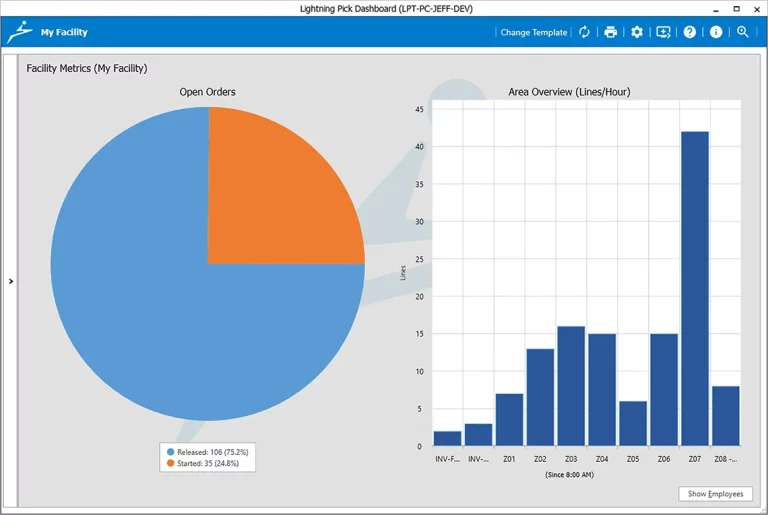

Finally, the ideal software streamlines and aggregates data from all light-directed systems, in real time, and display that information in a dashboard view. This enables complete collections of performance data to be viewed facility- or network-wide, or for drilling down into unique systems for a closer look at productivity or operational status in order to enhance fulfillment operation performance upstream, downstream and across all sub-processes within the 3PL or 3PF.

Rapid Results

Matthews’ Lightning Pick has delivered proven results to many leading third-party providers. Many of these advantages were gained within months of system implementation, enabling a rapid ROI and expansion of our systems to other areas and operations requiring optimization. Our customer Capacity has progressively and successfully implemented Matthews Automation solutions for their fulfillment systems, and a video case study is available here on our blog.

Stay tuned for future articles about choosing the right light-directed system for your third party fulfillment.