Leveraging the strengths of four of its brands, Matthews’ MODEX 2018 booth features a fully automated inbound receiving solution that decodes labels, reconciles received items, and routes cartons and parcels to their next destination with autonomous mobile robots

WILSONVILLE, OR — Visitors to Matthews Automation Solutions’ Booth B3763 at MODEX can tour a fully automated inbound receiving demo that integrates solutions from four of the company’s brands: Compass Engineering, Guidance Automation, Holjeron, and RAF Technology. The system—which reads and decodes labels, reconciles received items, directs cartons and parcels to their next destination, and flexibly navigates with autonomous mobile robots—will be on display throughout MHI-sponsored MODEX in Atlanta’s Georgia World Congress Center, April 9–12, 2018.

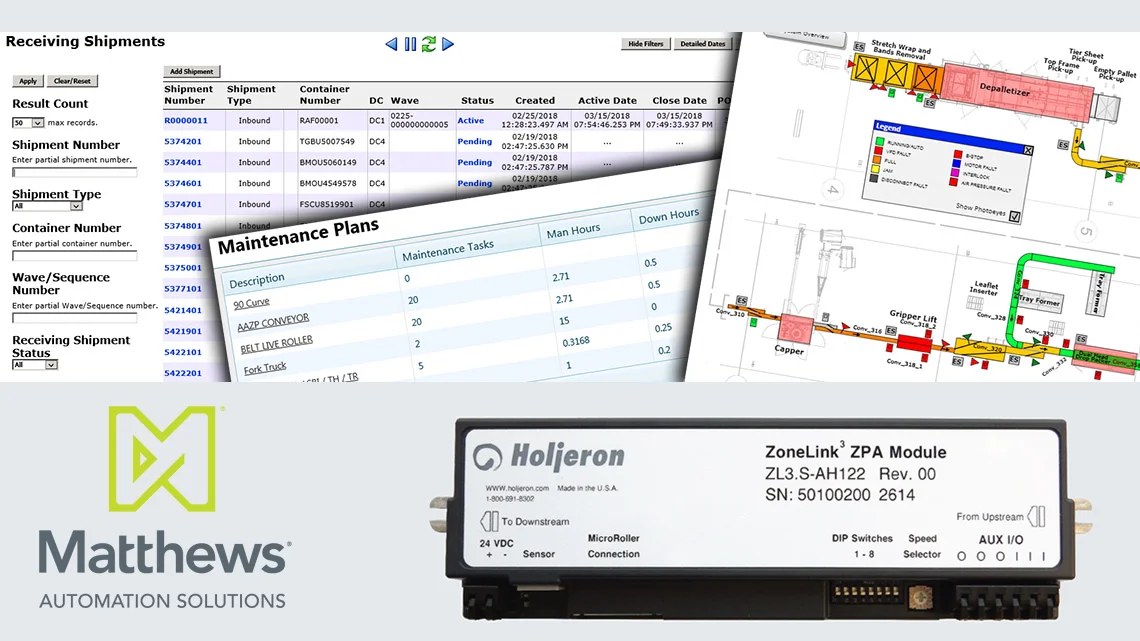

The demo automates the data capture and routing of individual cartons as they are unloaded from the back of a trailer parked at a receiving dock. As cartons are removed from the truck, they travel one-by-one down a motor-driven roller (MDR) conveyor controlled by Holjeron’s ZoneLinkTC™ controllers (which also direct Microroller® Distribution LLC’s SmartRoller® and Microroller® MDR brands, as well as Interroll’s 6- and 8-pole conveyor motors).

Each carton passes under smart vision sensors employing RAF Technology’s Optical Character Recognition (OCR) software to detect and decode data printed anywhere on the box or shipping label. RAF’s state-of-the-art, deep learning neural networks also enable recognition of data or labels in virtually any condition—including damaged or faint imprints.

The data collected about each carton is processed by Compass Engineering’s warehouse management software (WMS) and controls—CORS, the Compass Order Routing System—which reconciles the received cartons against advance shipping notices (ASNs) and assigns each to a subsequent destination: reserve storage, forward pick zone, or pallet for cross-docking. This software is part of Compass Engineering’s warehouse execution system (WES), which also includes the web-based Open Control platform that connects and optimizes a wide spectrum of automated material handling equipment. These fully integrated systems boost flow and throughput across the entire order fulfillment process for retail, direct-to-consumer, parcel and other high-volume DC operations.

The carton then passes from the in-bound receiving conveyor onto one of a fleet of Guidance Automation’s iNcaart autonomous mobile robots outfitted with an MDR attachment on top. The MDR and robot controls communicate to smoothly transfer materials from one another. Guidance’s SCENE natural feature navigation system directs the robot’s travel to other powered or non-powered conveyors, pallets for cross-docking or directly to picking and sortation areas for pick-to-light, put-to-light, automated loop or case sorters and more.

“This solution represents how the combined expertise of Matthews Automation’s brands can produce unique and flexible applications, ideal for distribution centers evolving into efficient, automated direct-to-consumer fulfillment operations. Integrated solutions like the inbound receiving system can greatly minimize labor requirements while increasing both throughput and accuracy in handling a large variety of high-speed, in-bound cartons or parcels. Our priority is to demonstrate the possibilities created when innovation and industry knowledge are seamlessly interwoven.”

-George Harbachuk, VP of Marketing for RAF

# # #