Robotic Integration into your Warehouse by Lynn Drewicz

Mobile Robots for Picking Orders

Are autonomous mobile robots right for your distribution centers or fulfillment operations? This article will help you explore several important considerations and also includes resources – such as a downloadable white paper – that will walk you through the next steps in planning your AMR implementation.

First, what is an autonomous mobile robot (AMR)? An AMR is a mobile vehicle that moves its payload independently and flexibly through an environment, often a distribution center or warehouse. There are many tasks that an AMR is ideally suited for, such as material transport, AMR-assisted order picking, interacting with conveyors, and other material handling tasks.

Some AMRs can have application-specific attachments for carrying certain types of payloads, such as shelves for bins or boxes, motorized roller conveyors, garment on hanger or even put-to-light bins for batch sortation (see image below). Among other things, AMRs can be ideal in supporting low-density, e-commerce picking activities. With the rapid growth of e-commerce order fulfillment, AMRs can be a beneficial tool in your e-commerce fulfillment operations.

Using Mobile Robots for Order Picking Can Result In

- Increased throughput and productivity

- Lower labor costs

- Greater flexibility; quicker material transport

- Decreased order processing time (or returns processing time)

Evaluation of AMRs

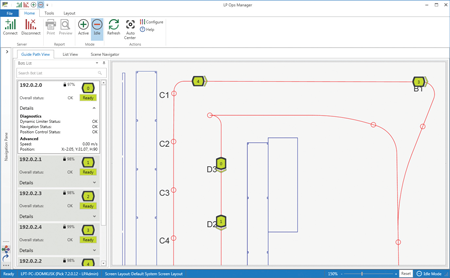

There are some important considerations when it comes to evaluating AMRs for your operations. Scalability and integration are important, as most companies choose to implement and integrate a small number of AMRs into the operations before employing a larger fleet. Computer-based simulations of your warehouse with AMRs can be a low-cost way to test different installation or process variations and can sometimes make the difference between a highly-successful versus a marginally-successful AMR implementation.

Software Systems Integration is Key

Integration with existing warehouse software is a very important part of implementing AMRs for picking orders – one that is too commonly overlooked when choosing a robotics vendor. Software integration needs to be evaluated carefully to make sure there aren’t any unforeseen hurdles in implementation and deployment. The AMR fleet management software needs to integrate with WMS, WES, WCS and/or MES systems and controls, as well as applications for pick-to-light, put walls, conveyors and other material handling automation. This ensures optimal AMR movement in the environment, resource allocation, and process throughput.

The Incremental Benefits of Autonomous Mobile Robots

- Reduce labor requirements – Especially helpful during peak season as AMRs can be deployed easily.

- Material movement flexibility – Less “fixed” infrastructure like conveyors; AMRs share space with humans and other equipment.

- Greater efficiency in picking and putting – AMRs can drop off the load at the put wall for sorting/shipping, for example.

- Safety – Designed to work with and around humans, each other, and to stop for people and unexpected obstacles.

- Operational visibility / optimize process – Real time visibility and operations dashboards provide managers with information needed to help improve and optimize their order fulfillment processes.

- Ergonomics – AMRs handle repetitive tasks and carry heavy items so that employees don’t get injuries.

Quick Resources on How to Implement AMRs

Step 1.

Download our free AMR white paper: “How to Successfully Implement Autonomous Mobile Robots into Order Fulfillment” – Includes 8 tips for successful AMR implementation!

DOWNLOAD WHITE PAPER (PDF)

Step 2.

Watch a 4-minute video on how robots fit into distribution centers by our VP Gary Cash:

Step 3.

Watch a 4-minute video showing technology, simulations and customized attachments for specific AMR applications:

Take Further Action to Evaluate Your AMR Needs

Autonomous Mobile Robots require special planning and simulations for optimal integration into your existing warehouse processes and automation. Contact us at Matthews Automation for a software demo, personalized ROI calculation and additional information on order fulfillment automation. Matthews Automation Solutions provides warehouse automation, including Warehouse Execution Systems, and is the number one provider of light-directed order fulfillment solutions in North America.

Watch for future blogs exploring warehouse execution systems, light-directed sortation and other advanced automation solutions.

About the Author

Lynn Drewicz, Matthews Marketing Manager, has worked with many global manufacturers and material handling suppliers, from custom technical ceramics, metal fabrication and membrane switches, to industrial samplers, heat exchangers, batteries and automation products. Her hobbies include tennis and music.