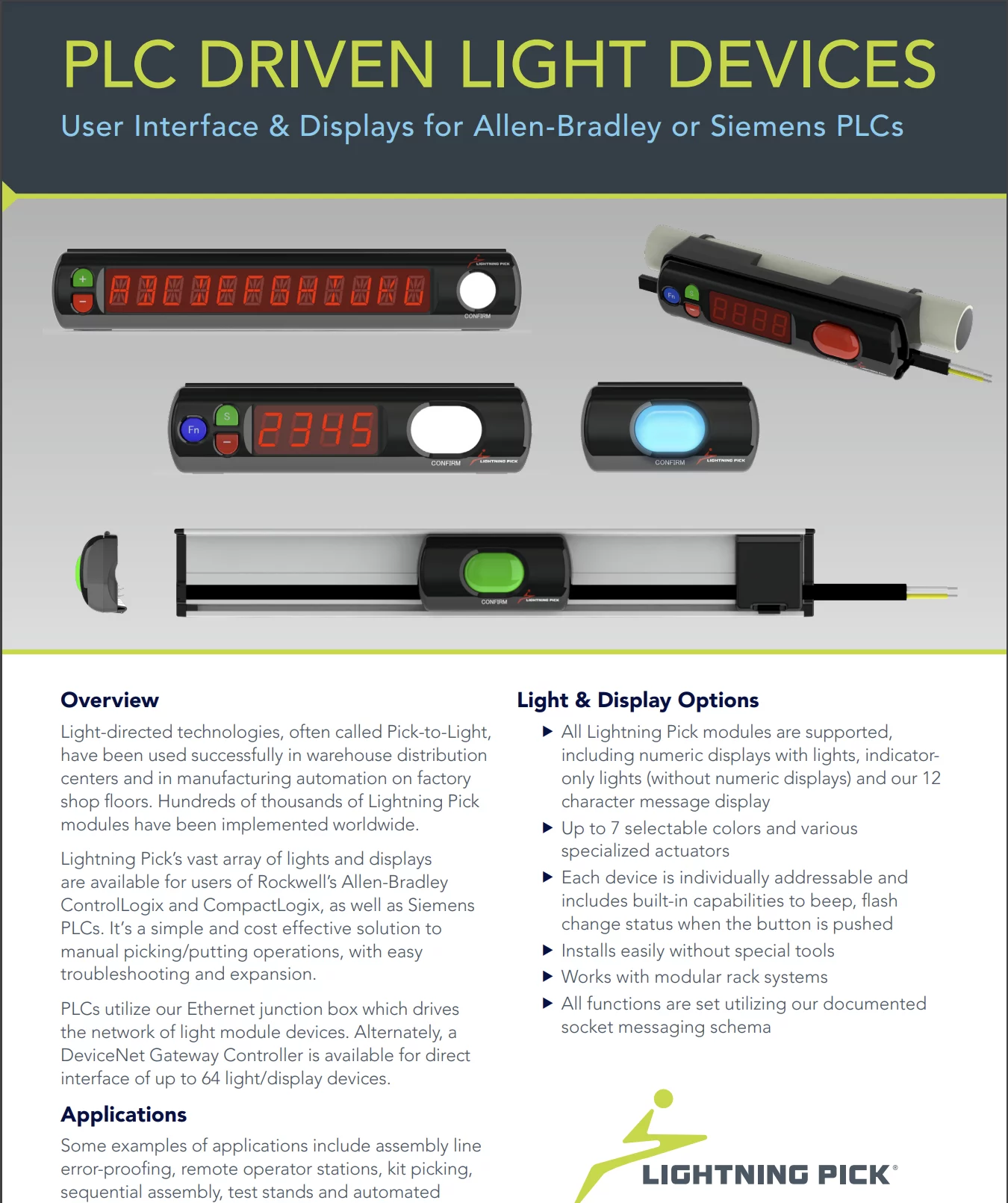

PLC Driven Lights & Display Devices

Lightning Pick’s vast array of lights and displays are available for users of Allen-Bradley ControlLogix and CompactLogix, and Siemens PLCs.

Lightning Pick’s vast array of lights and displays are available for users of Allen-Bradley ControlLogix and CompactLogix, and Siemens PLCs.

Matthews Automation Solutions’ light-directed pick carts provide productivity gains (up to 40%) and nearly 100% order accuracy compared to paper-based picking or operations using a standalone form of pick automation

With Pack-to-Light, cases of merchandise are routed to the DC’s break pack area. An operator scans the case and lights illuminate, directing quick sortation of the product to the right store carton and in the right unit quantities. Once the product is put to the store carton, the light module is extinguished to confirm the activity was completed.

With Put-to-Light, operators scan an item, and immediately the location representing an order illuminates. Workers distribute items accordingly, and extinguish the light once each task is complete.

This best-of-breed solution increases pick rate productivity, order accuracy and cost efficiency. With pick-to-light, lights are mounted to flow rack, shelving, workstations or other material handling media. The lights illuminate to show operators the correct pick locations and quantities required to complete an order.

With Matthews NEXUS Warehouse Execution System (WES), waving can be dynamically configured to meet new operational requirements. Utilizing a WES often saves money and increases flexibility as compared to a traditional WMS. The WES manages batch creation from a pool of orders; waving can be based on various performance objectives.

NEXUS utilizes real-time data to make intelligent decisions to boost picking, order management, and batching. Advanced algorithms eliminate bottlenecks and maximize productivity rates by moving work to where it is needed, adapting to fluctuations throughout the day. Adaptive Intelligence streamlines warehouse management, and NEXUS unifies data, operations and material handling equipment, enabling them to function collaboratively and increase throughput and material flow throughout the facility.

Matthews NEXUS warehouse execution system (WES) interfaces with the WMS or ERP system to automatically sync inventory counts between systems and adjust quantities as needed. In addition, NEXUS synchronizes Item Master Management data to the WMS to update key inventory information including manufacture date, lot number, and units of measure.

Matthews NEXUS Warehouse Execution System (WES) dynamically prioritizes and releases picks as waves, batches, or as-needed via a pull system. Continuous picking and customizable process management based on SLA requirements ensure that pick operators always receive a steady number of picks to complete, rather than waiting for a new wave to be released.

Cartonization is the process of determining the size and number of shipping cartons needed to fulfill an order based on the dimensions and weight of the contents. Matthews Automation Solutions NEXUS warehouse execution system (WES) utilizes data from scales and dimensioners or WMS downloads to automatically determine the amount of space and materials an order requires, saving time and money.