by Lynn Drewicz

What is Put-to-Light?

Put-to-light is an ideal technology for e-commerce fulfillment of consumer goods that can fit into bins or totes, such as apparel, accessories, jewelry, cosmetics, nutraceuticals, electronics, toys and all types of packaged goods. Do you have a busy e-commerce fulfillment operation with lots of SKUs? Consider implementing put walls in your organization.

What is a Put Wall?

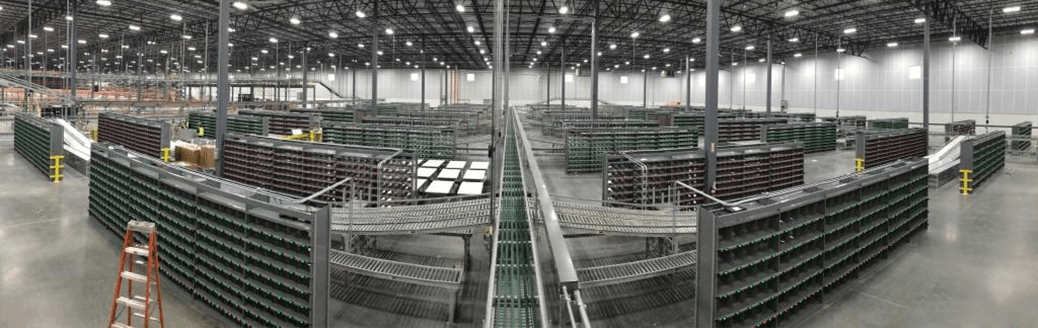

Used in high-efficiency batch picking operations, put-to-light stations – commonly known as “put walls” – are essentially pick-to-light in reverse. (Pick-to-light systems have lights at every pick face, whereas put walls have light modules located on the final sort location where orders are sorted into empty bins, totes or shelves/cubbies.) The complexities of sorting diverse, multi-line orders are made simple and fulfillment errors are drastically reduced, with a 99% accuracy level, thus reducing rates of returns.

Put Walls Can Help With:

- E-commerce order fulfillment

- Secondary batch pick sortation

- Sortation to customer orders at discharge of loop sorters

- Soration to customer orders in goods-to-man applications

- Returns processing

How a Put Wall Works

At the put wall, a tote of batch-picked, mixed-SKU merchandise is sorted into individual direct-to-consumer or e-commerce orders. The software uses a “batch wave file” on the front end – integration with warehouse software and shipping software makes the whole process go smoothly, from pick to pack to ship.

The sorting process itself is quick and efficient: when the merchandise is brought to the put wall, the operator scans an item and immediately puts it into the bin illuminated by the put-to-light module. He or she then pushes the button/light to turn off the light and confirm the put. The operator continues to sort all the items from the batch-picked tote into individual orders with this easy and highly accurate technique. Packing slips and other inserts can be scanned and placed with the orders, also. When an order is complete, the light-directed picking module indicates that the order is complete and ready to ship.

This put wall video features introductory demonstrations of light-directed put and pack systems in action.

At the put wall, a tote of batch-picked, mixed-SKU merchandise is sorted into individual direct-to-consumer or e-commerce orders. The software uses a “batch wave file” on the front end – integration with warehouse software and shipping software makes the whole process go smoothly, from pick to pack to ship.

The sorting process itself is quick and efficient: when the merchandise is brought to the put wall, the operator scans an item and immediately puts it into the bin illuminated by the put-to-light module. He or she then pushes the button/light to turn off the light and confirm the put. The operator continues to sort all the items from the batch-picked tote into individual orders with this easy and highly accurate technique. Packing slips and other inserts can be scanned and placed with the orders, also. When an order is complete, the light-directed picking module indicates that the order is complete and ready to ship.

This put wall video features introductory demonstrations of light-directed put and pack systems in action.

Double Duty – Put and Pack Orders

Matthews Automation Solution’s two-sided put wall solution offers lights on the opposite side of the put wall as well. When individual orders are completed, packing personnel see that the order is ready to ship and specific carriers can even be called out on the light module (see photo below). This unique put system can be used for box kitting, pack-out (as shown) and other value-added services. Alternative, flexible software and hardware configurations are also available to best balance workflow across both put and pack tasks, depending on volume and unique process requirements.The Benefits of Put Walls for Growing E-Commerce Businesses

- High order fulfillment productivity at high speeds – Many online retailers say that put walls have proven themselves in providing the speed and accuracy needed to support high customer demand in growing online businesses.

- Increased accuracy – The product is scan-confirmed right before it is placed into the order location.

- Economical use of space – The small footprint and ease of relocation of put walls allows for maximum space efficiency, with the ability to add capacity and additional put walls for growth and throughput when business increases.

- Scalable for future growth – Additionally, major gains in operational efficiencies provide added capacity within existing infrastructures to scale up for the growth of the business.

- Operational visibility / optimize process – Real time visibility and operations dashboards provide managers with information needed to help improve and optimize their order fulfillment processes.

- Handles complexity / integrates easily – Integration with WMS/WES/WCS/ERP software provides a complete sort-and-ship solution.

ABOUT THE AUTHOR

Lynn Drewicz, Matthews Marketing Manager, has worked with many global manufacturers and material handling suppliers, from custom technical ceramics, metal fabrication and membrane switches, to industrial samplers, heat exchangers, batteries and automation products. Her hobbies include tennis and music.